Key numbers

About the San Gabriel Valley Water Company

San Gabriel Valley Water Company (SGVWC) is an investor owned public utility water company regulated by the California Public Utilities Commission (CPUC). SGVWC has two operational divisions: the Los Angeles County division (LAD) and the Fontana Water Company (FWC) division.

The FWC serves a 52 square mile area that includes the communities of Fontana, Rialto, Rancho Cucamonga, Ontario, and unincorporated areas of San Bernardino County. FWC has the flexibility to receive water from both groundwater, local surface water, and imported State Water Project (SWP) water supplies. Ground water supplies include Chino Basin, Rialto Basin, Lytle Creek Basin, and No Man’s Land Basin.

Local surface water supplies and SWP supplies are treated at the Sandhill Water Treatment Plant (Sandhill) and come either from Lytle Creek or the SWP. SWP supplies are purchased by FWC from either Inland Empire Utilities Agency (IEUA) or San Bernardino Valley Municipal Water District (SBVMWD). IEUA purchases SWP water from the Metropolitan Water District (MWD) for wholesale redistribution to a number of water purveyors, including FWC.

Case study participants

The challenge

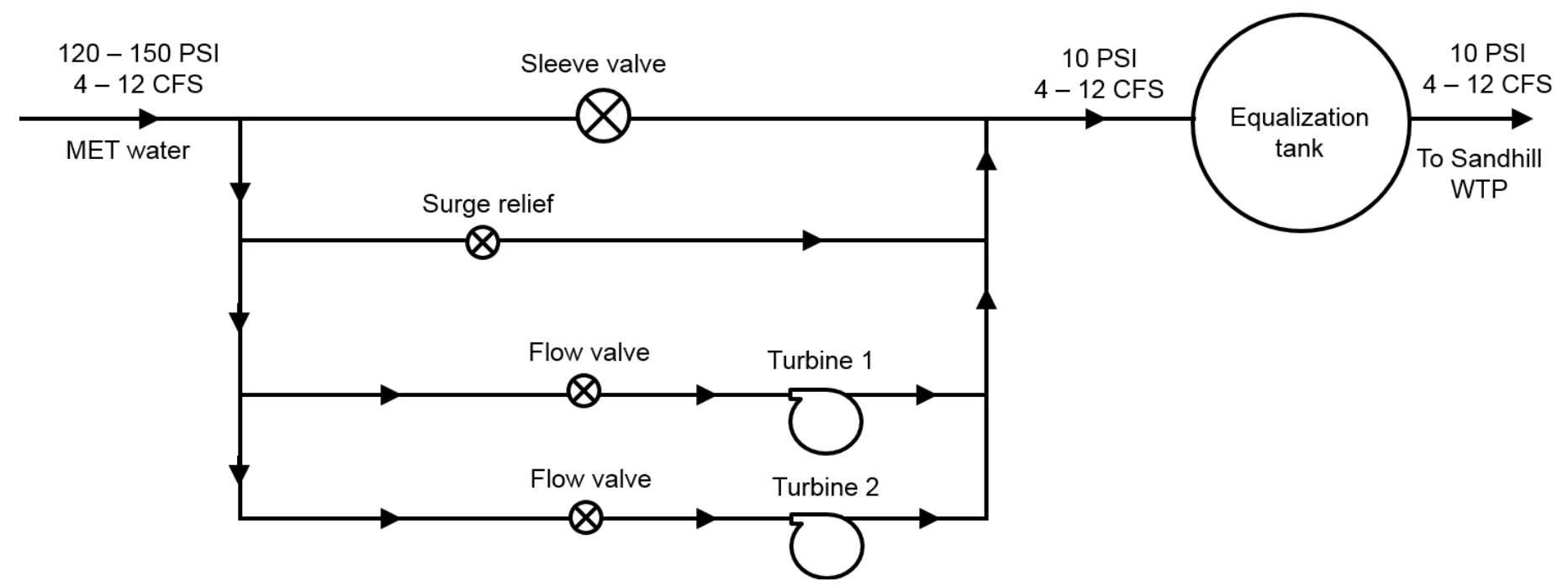

The IEUA supply pipeline (capacity up to 40 cubic feet per second) enters Sandhill at approximately 120 – 150 PSI through an on-site pressure reducing station (PRS). A sleeve valve is used as pressure reducing valve (PRV) to reduce the pressure to 5 psi. Flow rates are manually adjusted and selected by operations personnel ranging from 4 cfs to 13 cfs.

The hydropower station is installed in parallel with the sleeve valve to harness the excess energy. The schematic flow diagram of the hydroelectric station is presented in Figure 1 below. The hydropower station consists of two pump-as-turbine (PAT) units with total capacity of 310 kW (one operates at 1800 gpm, and the other at 3600 gpm). All the generated energy is exported to the grid and FWC receives credit based on the energy consumption in Sandhill WTP at the same tariff as what they would have paid. As of February 2018, the annual power generation was about 1,121,087 kWh, which was used to offset power in the facility (606,808 kWh). FWC received about $12,000 from the Southern California Edison (SCE) for the excess energy generated (514,279 kWh).

Figure 1. Schematic flow diagram of the hydroelectric unit at Sandhill Water Treatment Plant

Project drivers

SGVWC has long recognized the large energy potential embedded in their systems which could be used to offset the energy in their facilities. From the public policy perspectives, there were also initiatives from the California Public Utility Commission (CPUC) to direct utilities to gain better understanding of the water-energy nexus in their systems.

In the proceedings, utilities were recommended to estimate the potential embedded energy in their water distribution systems and identify the potential use of this excess energy. SGVWC considered this concept to be attractive as any saving that the facility achieves can indirectly impact customers through lower water bill. After discussion with the board, SGVWC decided to contract with NLine Energy to assist with the development of hydropower station at one of the facilities. NLine Energy also assisted SGVWC in securing some of the funding, which was one of the most important factors in the advancement of this project. SGVWC received a cash grant from U.S. Treasury (1603 U.S. Treasure Grant) which covered 30% of the total project cost for eligible renewable energy projects as well as incentives from Self-Generation Incentive Program (SGIO) sponsored by CPUC.

Feasibility Assessment

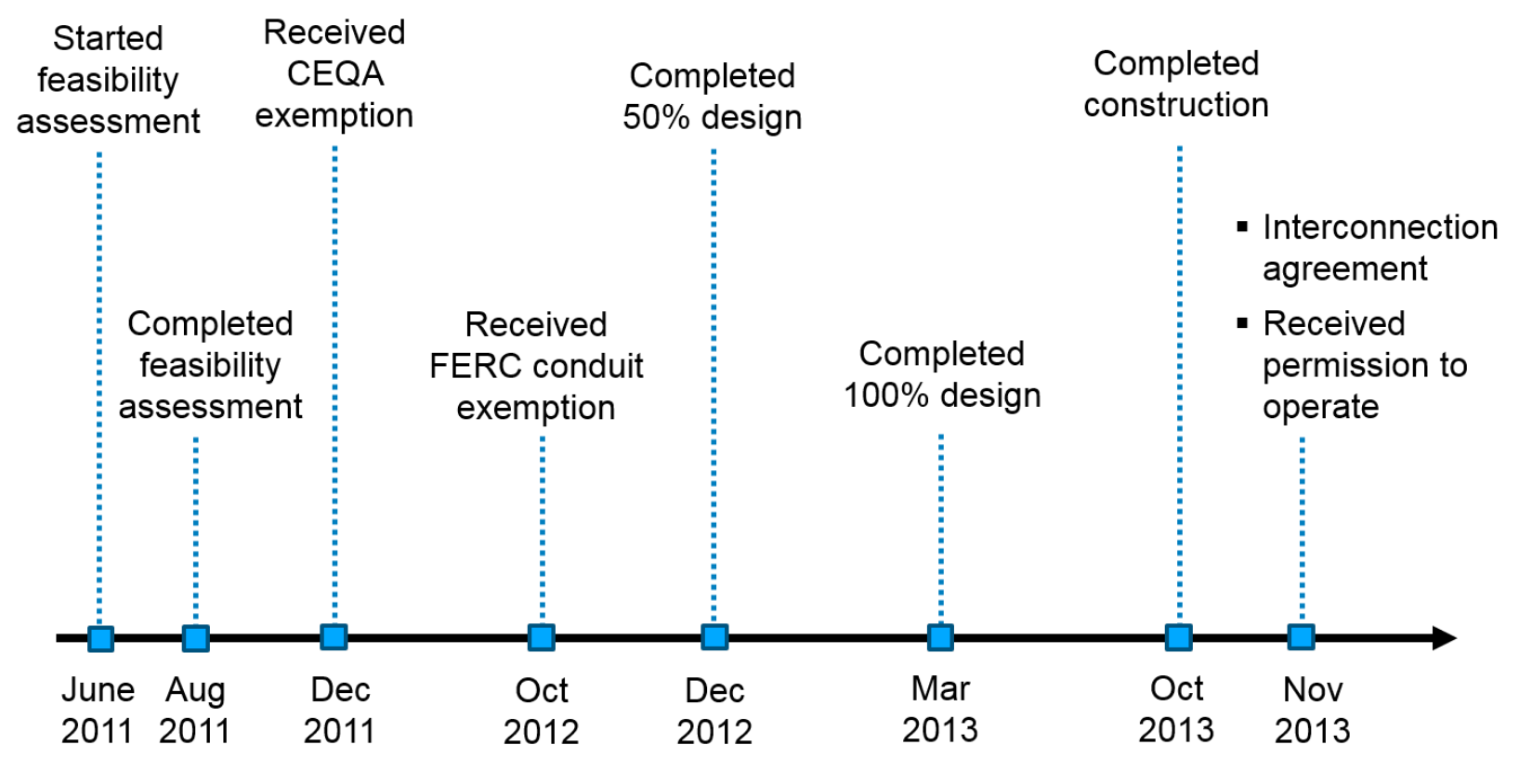

SGVWC conducted an initial feasibility assessment of the potential project between June and August 2011 (see Figure 2 for project timeline) and identified three alternative locations within SGVWC systems: F13, F14 (Sandhill), and F19. Initial assessment showed that location F14 in Sandhill Water Treatment Plant (managed by FWC) to be the most economically feasible site due to its large pressure differential (breaking 120 – 150 psi to 10 psi). There was also negligible change in the flow rate in this particular pipeline during 24/7 operation (4 – 13 cfs, but generally stays around 10 cfs).

Based on these conditions, two types of turbines were proposed: Pump-as-Turbine (PAT) and Francis turbine. For Francis turbine, flow can be varied to accommodate supply or demand variations but at the expense of reduced efficiency and power generation. A Francis turbine also becomes unstable below 40 percent of full flow and does not operate well at less than 40 percent of full electrical load. Thus, it was determined that installation of two Pump-as-Turbines (PAT) would be most suitable for the site. The twin PATs operate in both sequence and parallel, enabling the system to process flows ranging from 4 cfs to 13 cfs with a system nameplate rating of 310 kW.

The feasibility assessment determined if the project was feasible from an economic, environmental, technical and regulatory perspective. This preliminarily assessment took approximately 3 months to finish and determined that the initial project cost was approximately $1,400,000, would generate approximately 1,000,000 kilowatt hours annually and would have a sub 10-year payback.

It is also important to note that these estimation were made based on the assumption that the IEUA’s water uptake capacity was 5000 acre-feet/year which would be taken over a period of approximately seven to nine months, depending on hydrology and water demand. After conducting the feasibility assessment, FWC proceeded to complete 100% design in March 2013, and finally received the permission to operate in November 2013. It took approximately 2 years to complete the project, as depicted by Figure 2 below.

Figure 2. The timeline of the project starting from feasibility assessment to operation startup

Permitting and Regulation

California Environmental Quality Act (CEQA)

The California Environmental Quality Act (CEQA) allows a Class 28 Exemption for small hydroelectric projects. Section 15328, titled, “Small Hydroelectric Projects at Existing Facilities”. This project meets most of the physical requirements for a Categorical Exemption (CE), however further assessment of the system was conducted to determine if: (i) the project will not entail any construction on or alteration of a site included in or eligible for inclusion in the National Register of Historic Places and (ii) any construction will not occur in the vicinity of any rare or endangered species. To address these issues, SGVWC obtained biological and historical databases including;

- California Natural Diversity Database (California Department of Fish & Game)

- Biological databases of the U.S. Fish and Wildlife Service

- Historic Resources Record Searches

Through assessment of these databases, SGVWC provided full evidence that that its system was eligible for CEQA exemption and Notice of Exemption (NOE) was submitted to the Lead Agency (City of Rialto, California). CEQA exemption was obtained in December 2011, as depicted in the project timeline above (Figure 2).

FERC Conduit Exemption

Under the Federal Power Act (FPA), Federal Energy Regulatory Commission (FERC) regulates the nation’s non-federal hydropower resources. As of 2012, FERC issued three types of development authorizations: conduit exemptions, five-megawatt (MW) exemptions, and licenses. In order to qualify for a conduit exemption (less than 40 MW), the following criteria must be met:

- The hydro generator must be installed on a conduit constructed primarily for non-hydropower purpose;

- It must be located on a conduit used for agricultural, municipal, or industrial consumption; and

- The applicant must own the proposed powerhouse and the lands upon which the powerhouse will be located

The FERC conduit exemption was issued in perpetuity, and projects up to 5 MW were not charged an annual fee. This project qualified and secured the FERC conduit exemption in October 2012. Note that at this time FERC had not simplified its regulation processes for small hydropower projects as the “Hydropower Regulatory Efficiency Act” was only signed in August 2013. This project could have been eligible as Qualifying Conduit Hydropower Facility, which is not required to obtain license or exemption from FERC. Eligible facilities must only file a Notice of Intent (NOI), thus the process is significantly faster (about 45 days) than exemption or licensing processes.

Design and Construction

NLine Energy provided the design of the powerhouse as well as technical expertise throughout the entire project. However, FWC utilized service from the same contractor that built the water treatment plant (RC Foster) during construction. Using the same contractor was considered to be beneficial for a retrofit project as the contractor was already familiar with the existing system.

The hydroelectric station was constructed parallel to the existing sleeve valve adjacent to and south of the existing vault structure (refer to Figure 1). The existing 30-inch tees (MWD water pipe) remains in their current location and new pipe connects to the existing tees and extend through the vault walls utilizing the cutouts already existing in the vault wall. The new hydroelectric station is supported on a new concrete slab and is housed in a pre-fabricated metal building approximately 24-feet by 20-feet in dimension. Flow is diverted upstream of the sleeve valve to the intake side of the hydroelectric station. Upon exiting the hydroelectric station, piping reconnects downstream of the sleeve valve at the existing 30-inch tee. Flow is measured utilizing the existing flow meter. Supply in excess of optimum flows through the existing sleeve valve. A surge relief valve is also available to protect from excess pressure that might damage the turbines. A building housing the units was constructed for sound attenuation as the turbine-generator was designed for indoor exposure only. The switchgear is also housed inside the turbine-generator building. Re-grading of the site outside the vault structure was necessary.

Since the hydroelectric station was constructed upstream of the water treatment plant, the design flow and pressure for the turbines were determined based on downstream WTP requirements. During the design stage, FWC also specified that 5,000 acr-ft of water from IEUA would be taken over 12 month period. Based on this information, 4 – 12 cfs was determined as the range of design flows that would allow FWC to achieve the 5,000 ac-ft goal, assuming the differential pressure of 130 psi. In order to allow for flow selection flexibility, two PATs were selected. The lead PAT can pass approximately 4 cfs (1800 gpm max) and the lag PAT can pass approximately 8 cfs (3600 gpm max). Both PATs operating together are expected to process up to 12 cfs and produce 310 kW maximum for the hydroelectric station. Photographs of the twin PAT units during construction and operation are provided in Figure 3.

Figure 3. Photographs of the hydroelectric units during construction (left image) and operation (right image)

Since the power generated was planned to be exported to the grid, construction pertaining to interconnection with existing utility service connection was also conducted. Since this facility is the first small hydropower facility in the last 20 years to connect with Southern California Edison (SCE) lines, a new pole with an upgraded reclosers to protect the grid was installed at the facility. FWC was also required to expand the power service to 12 kV powerline.

Operations and Maintenance

The hydroelectric station operates based on flow and pressure supplied from the IEUA pipeline. FWC Operations personnel will determine how much flow is required from the IEUA supply line and manually set the flow as their normal practice. The IEUA source has relatively constant pressure, ranging from approximately 120 psi to 150 psi. This stable pressure in addition to the fact that FWC can set a constant flow greatly increases the operational controls for the turbines, which therefore increases efficiency and simplifies operation. The FWC operators determine their desired flow to Sandhill and set the flow coming into the Pressure Reducing Station and the sleeve valve will operate as normal. Depending on how much flow is desired for operation of the hydroelectric units, the sleeve valve will reduce flow, via a SCADA signal and divert the desired portion of the flow into the hydroelectric station. Flows less than the capacity of the hydroelectric station will be processed through the sleeve valve only. Flows in excess of the hydroelectric station capacity will be divided such that the hydroelectric station will process as much flow as possible, with the remainder proceed through the sleeve valve. Control valves to each hydroelectric unit control on/off operation of the hydroelectric units. Control logic is programmed to select flow to each hydroelectric unit with flow trim being accomplished by the existing sleeve valve.

The two turbine-generator units are controlled through a Programmable Logic Controller (PLC) that engages one or both units depending on the flow and head available for maximum efficiency. An rpm tachometer monitors for speed and once it is close to the utility frequency (approximately 1,800 rpm and 60 Hertz (Hz)), the tachometer allows the close of the motor contactor. The turbine control valve continues to open and load the generator until at maximum flow and load. Once a generating unit(s) is on line, an rpm tachometer will monitor for speed and frequency. The turbine control valve will continue to open and load the generator until at maximum flow and load.

Typical maintenance of a hydroelectric station includes the following:

- Daily inspections of the hydroelectric station are recommended to detect leaks, excessive moisture buildup, loud noises, excessive vibration and/or heat. Sensors may be used to remotely detect many of these issues to augment physical inspections;

- Quarterly oil inspections / change: bearings, hydraulic systems, and gearboxes require grease or oil. Annual inspection and testing for viscosity, acidity and water content are required, while minimizing different types of oil, if possible. If oil temperatures stay below 60˚C, the oil’s useful life is extended dramatically;

- Flow, pressure, and resulting kW production and overall efficiency should be checked periodically and instruments calibrated on regular intervals;

- The first inspection of the turbine itself should be at 12 months or 8,000 hours of operation;

- General inspections should occur every year until a history is established and trends are identified. Then the interval can be extended to two or more years. Similar installations may be good indicators of maintenance trends;

- Annual maintenance costs are assumed to be approximately $6,000 per year;

- Summary of annual maintenance and repair downtime:

-

- i. Assume one week each year,

- ii. Assume three weeks every five years,

- iii.Three months every 25 years

Costs and Financing

An overview of the project cost estimated at two different times (50% design and nearing completion) is provided in Table 1 below. During 50% design, the project cost was estimated to be around $1,675,000 with calculated payback time of 8.4 years. However, as can be seen, the total project cost increased by $485,929 over the course of 1.5 years during construction. One major cause of this cost increase was the unexpectedly high interconnection cost with the SCE as a new pole with upgraded reclosers must be installed.

The breakdown of the project cost as of April 2014 is also provided in Figure 4 below. As can be seen, construction was the major contributor to the total cost (40%) followed by engineering, planning, and permitting (31%). Interconnection cost was also considered to be significant in this case (13%) due to the need to update the outdated equipment owned by SCE and the fact that this project was one of the first small hydropower projects that interconnected with SCE in the last 20 years. The turbine-generator cost was not considered to be major as PATs are generally less expensive than other similar turbines such as Francis turbines.

Table 1. Overview of the project cost calculated in December 2012 (50% design) and April 2014 (nearing completion)

| Cost item | Cost | |

| December 2012 | April 2014 | |

| Total Project Cost | $1,675,000 | $2,160,929 |

| Federal Business Investment Grant (U.S. Treasury Grant) | $462,467 | $462,467 |

| Self-generation Incentive Program (SGIP) | $320,290 | $320,290 |

| Net Investment | $892,243 | $1,377,542 |

Figure 4. Breakdown of project cost as of April 2014

Future Planning

The Sandhill hydroelectric project has been operating for over four years and has met the initial estimations and expectations for the project, yielding no electric bill for the four years since commissioning using the Net Energy Metering tariff. As previously mentioned, FWC even received a $12,000 check from SCE as the facility has been generating excess energy. However, the tariff used for this excess energy is generally quite small and not attractive for small utilities that are looking to sell their energy.

The project’s success has led SGVWC to embark on another in-conduit hydroelectric project. The new project, named B24 Hydro Project, will implement an innovative “Plug & Play” design for a 73 kW pump-as-turbine. It should be noted that the B24 project is being partially funded by California Energy Commission’s (CEC) EPIC Grant.

Lessons Learned and Recommendations

- Scenario planning: During the feasibility assessment, the Sandhill plant has the ability to source water at different times of the year, which provided an opportunity to size the hydroelectric station for year-round, summer, and peaking scenarios. Summer and peaking scenarios aligned with the high time-of-use electric tariff rates that are normally charged to a customer for consumption of electricity during high-use times (peak demand hours). However, when a hydroelectric station is installed, the generation is credited at these high rates under California’s Net-Energy Metering rules. Small conduit hydroelectric projects should consider multiple scenarios at the feasibility stage to investigate these opportunities.

- Contractor for construction: FWC utilized the same service from the contractor that built the Sandhill WTP during the construction of the powerhouse. This is a useful strategy for a retrofit project as the contractor is already familiar with the existing system, thus minimizing any confusion and error that can occur during the construction period.

- Pump-as-Turbine technology: PATs are essentially pumps in reverse. Rather than pump water, the runners are manipulated towards energy recovery, which closely resembles a Francis-style turbine. PATs are fixed geometry units and lack any type of wicket gates that a typical Francis-style turbine would possesses. While PAT’s have narrowly defined head-flow operating curves, there are multiple versions that can be combined to manipulate a majority of the site flows without sacrificing potential generation. PATs are also one-third to one-quarter the total cost of a single Francis turbine, which opens up a sub-500 kW conduit hydroelectric market in the U.S. for this technology.

- Use of flow control valves upstream of the PATs: The contractor designed and integrated control valves upstream of the turbine, which allowed flows and heads to be manipulated to maintain high-efficiency on the PAT, while also ensuring consistent generation throughout subtle variations in flow that would have shut down the PAT without the use of the valves. This additional equipment increases generations, extends the life of the equipment and decreases O&M costs.

- Interconnection: The Sandhill hydroelectric project was one the first hydroelectric stations to interconnect to the Southern California Edison (SCE) distribution grid in over 20 years. Since hydroelectric turbines are rotating equipment (non-inverter) technologies providing reactive power to the grid, additional protective equipment is required as part of California’s Rule 21 interconnection standards. Throughout the interconnection process, SCE’s review and design process was elongated over 18 months given lack of staff awareness, fluency in reactive power equipment, and poor project management. While the project commissioning was slightly delayed, this project served as a case study for SCE and other investor-owned utilities to improve their knowledge and processing of small hydroelectric project interconnection applications.

Andrew Benjamin, NLine Project Manager

Are you sitting on a source of wasted energy? Would you like to convert this into clean, renewable power? Give us a call! You’ll get a free assessment with an expert who can instantly identify your opportunity.

Nate Turner, Chief Commercial Officer

Do you have steam? Would you like to make clean, renewable power? Give us a call! Our experts can instantly assess your opportunity.